Your cart is empty.

Tecan uses cookies to improve our website. By continuing to browse our website, you accept our cookie policy.

- Life

Sciences

- Products

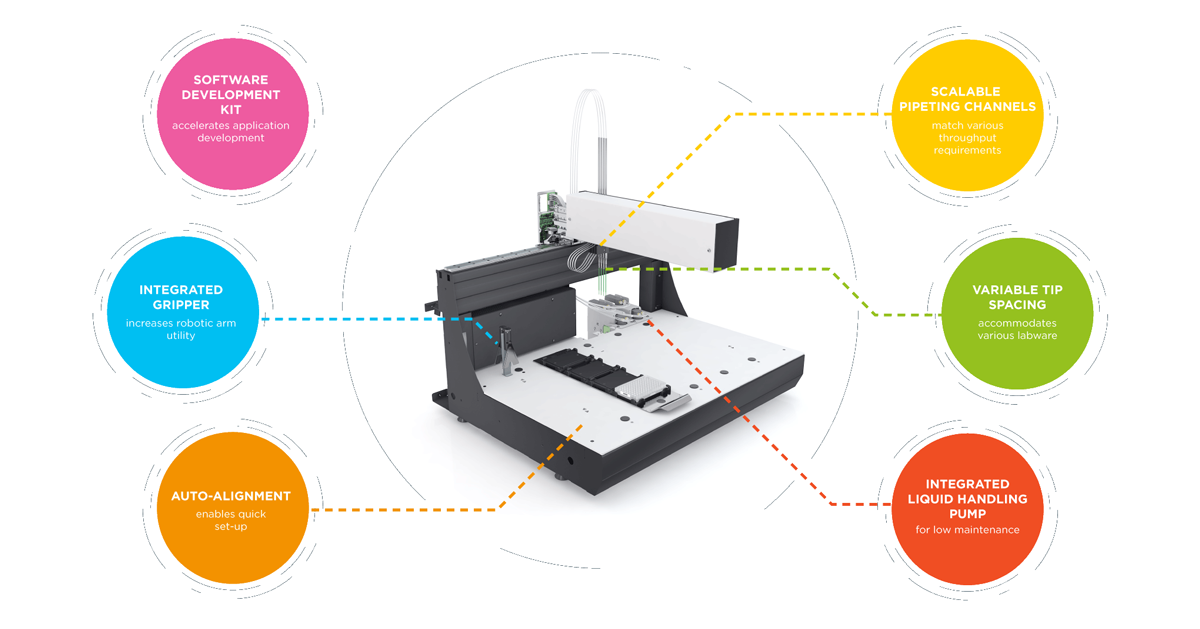

- Liquid handling & automation

- Tecan Labwerx

- Microplate readers

- Microplate washers

- Software

- Consumables

- Next generation sequencing

- Immunoassays & antibodies

- Applications

- Resources

- Products

- Diagnostics

- Products

- Liquid handling & automation

- Microplate readers

- Microplate washers

- Software

- Consumables

- Resolvex and smart consumables

- Immunoassays & antibodies

- Applications

- Case Studies

- Products